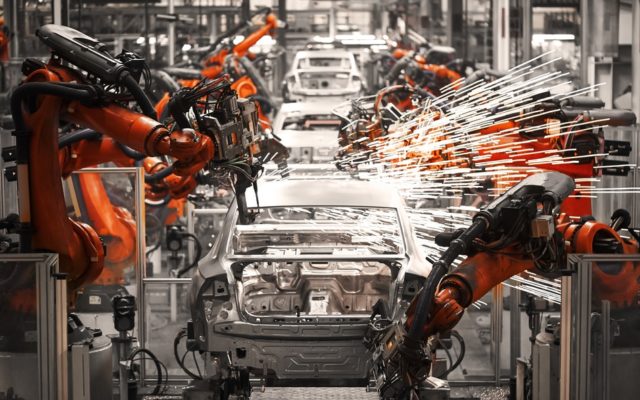

What is the factory of the future? Is it a synonym to Industry 4.0, or is it a different concept in its own right? Industry 4.0 and the factory of the future might sound similar, but they are different in some ways. To begin with, the factory of the future is an elusive concept that isn’t as common as Industry 4.0.

The factory of the future is meant to be your gateway to the future of AI and IoT. Through exploring my interest in the topic and as an Oracle ambassador, I had the opportunity to speak to Hans Michael Krause from Bosch Rexroth about the future of IoT systems. Michael, who is the Director of Product Management PLC and IoT systems, is an industry expert and knows quite a bit about the subject.

Talking to me Michael said that,

‘the factory of the future has elements of Industry 4.0, but it is integrally different from it. The factory of the future also talks about distributing your energy via inductive factory floor. It involves 5G connectivity, and is much more than the bland digitization offered by Industry 4.0. The factory of the future also involves collaborative robots, which are counted as a new trend in this realm. These are just some of the many dreams that are phasing out to be true through the collective efforts of scientists in the factory of the future.”

Michael and I then went on to discuss other topics that will have a bearing on the industry of the future, for example the factory of the future bringing exceptional connectivity. One example in this instance could be that of Oracle ERP Cloud, which connects factory data with back office solutions. Additionally, the concept also entails connectivity from the manufacturing to the selling of the product. Manufacturers, hence, should educate themselves to be on par with the trends around them.

There are going to be challenges impeding the path towards the overall implementation of the factory of the future. These challenges include the understanding of the new technology ready to make its way within organizations. The necessary priority and resources will be required to better understand, embrace and ascertain how to effectively leverage technologies like blockchain, IoT and AI in ways that create business differentiation and advantage for customers.

Moreover, the presence of siloed data within the business operations can lead to numerous complications, including tracking and tracing parts and products life and availability within the supply chain. Finally, limited connectivity between the user and the producer can also hinder progress for the factory of the future.

6 steps for factory of the future

As part of our conversation, Michael pointed out the 6 steps Bosch Rexroth defined for the seamless integration of the factory of the future within your setup:

- Lean Manufacturing: Lean manufacturing is an efficient system of production that finds its roots in Japan. The manufacturing process is based on limiting any inefficiencies and wastages within the business processes.

- Connectivity: Connect manufacturing, production and assembly data to give enhanced visibility of processes.

- Generating Data: Generate data with a closed loop approach. Gather data at different phases, and make sure that it is trustable. Closing the loop will drive efficiency of your equipment.

- Obtaining Info from Data: Obtaining information from your data is the most important step after you have gathered and stored it. Raw data alone doesn’t hold much business value. It’s the information and patterns extracted from data that gives you an advantage over competitors.

- Insights from Information: Once you have obtained information from your data, you can start extracting insights. Use insights to further effect, take decisions that make sense in the business structure.

- Fully Flexible Factory: A highly flexible factory in which everything except floor, roof and walls is changeable within days or even hours. The production is independently adjusted to the product to be manufactured.

Jumpstart the journey to factory of the future

Tech-savvy manufacturers, like Bosch Rexroth, have begun to invest in the factory of the future, taking steps towards modernizing them and embracing innovations that drive connectivity between people, processes and machine data. Organizations taking this path can accelerate business, provide improved customer experience and gain competitive advantage, placing themselves in a good position within the manufacturing industry of the future.

Article by channel:

Everything you need to know about Digital Transformation

The best articles, news and events direct to your inbox

Read more articles tagged: Business Model, Featured, Strategy