Just recent I published a post entitled “The Three A’s of Predictive Maintenance” [Link] basically discussing the importance of maintaining assets in these current economically volatile times. The post does contain some references to IoT (Internet of Things), but here I want to concentrate what is really important, so I am going to steal the phrase from Mr Harel Kodesh, Vice President, Chief Technology Officer at GE, who introduced the phrase in his key note speech at the Cloud Foundry Summit in May of 2015 (http://youtu.be/cvIjvbjB7qo)

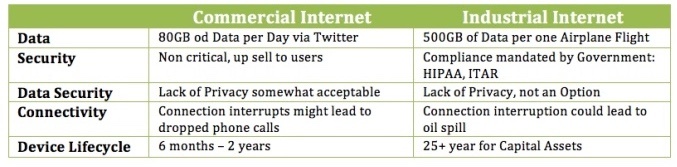

We build huge assets to support our way of living and these assets are the REALLY important things that without maintenance will disrupt everything if left to the “fix it when it breaks mentality”. Mr Kodesh uses two examples which I have explained in the table below, we have the Commercial Internet and we have the Industrial Internet.Both are equally as important as each other, but impacts on business and environment are much greater in the Industrial Internet and could have far reaching consequences.

When we wake in the morning we tend to think about having a shower and getting ready for work, cooking our breakfast either via electric or gas. We don’t think about the Water Distribution system, We don’t think about power generation or it distribution and we certainly don’t think about gas extraction or it’s distribution.We don’t think about the fuel or where it was made for the fight across the world for us to do business in another country. We are not sure about where the petrol or diesel comes from that powers are cars or trucks.

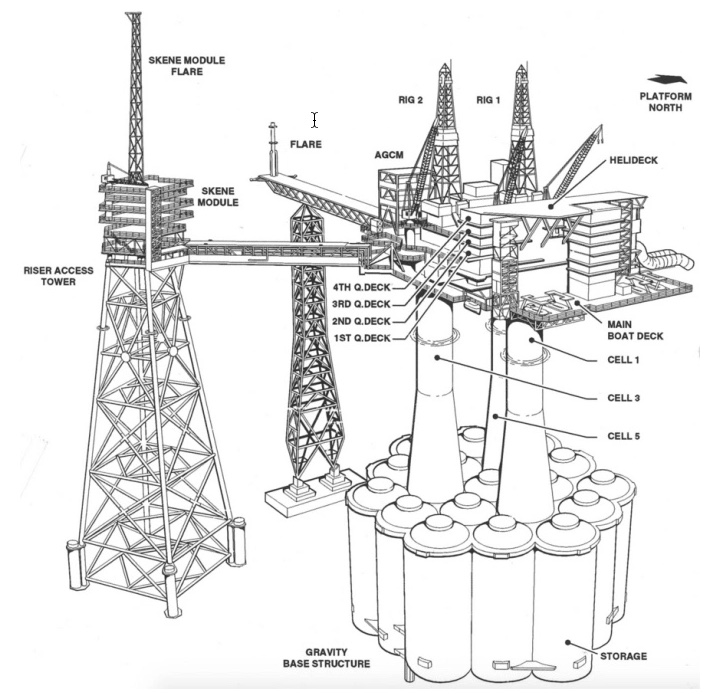

Well it’s reasonably simple to define, all of these commodities come from huge assets that may power other assets and have to be maintained. We are talking here about Oil & Gas Drilling and Production platforms, or Oil Refineries, or Power Stations. All of these asset include other assets which have to be maintained.

Above is a good example of what we are talking about and one that I was intimately involved with. Some 195 miles out to sea, the first concrete platform (Condeep, built by Aker in Stavanger, Norway ), the Beryl Alpha, was given a life expectancy of 20 years when it was installed by Mobil, now part of ExxonMobil, on the Beryl oilfield (Block 9/13-1) in 1975. Now 41 years on and being purchased from ExxonMobil By the Apache Corporation there is no sign of it being decommissioned and the addition in 2001 of facilities to process gas from the nearby Skene gas field has given it a new lease of life.

At its peak in 1984, Beryl Alpha was producing some 120,000 bpd. It is still pumping an average of 90,000 to 100,000 barrels of Beryl, a high quality crude (Beryl) named after Beryl Solomon, wife of Mobil Europe president Charles Solomon. Gas production is around 450 mm cfpd, representing nearly 5 % of total British gas demand or the needs of 3.2 mm households. Today “The challenge is the interface between technology 41 years old and new technology.”

So here we are thinking now about “The Internet of Really Important Things” and how we can use technology of today with the technology of yesteryear? Doing more with less, sweating the assets to coin a phrase! Compliance to specifications and rules and regulations, this is where we need tools and techniques such as Predictive Maintenance (PdM).The link specifications is a snapshot of specifications for the Beryl, monitors and sensor ensure that data is captured which as a result can be used to highlight problems before they occur, this information is being collected in realtime.

To achieve what it is called World Class Maintenance (WCM), it is necessary to improve adopted maintenance processes.Various tools available today have adopted the word maintenance. It is important to note that these are not new types of maintenance but tools that allow the application of the main types of maintenance.

Article by channel:

Everything you need to know about Digital Transformation

The best articles, news and events direct to your inbox

Read more articles tagged: Featured